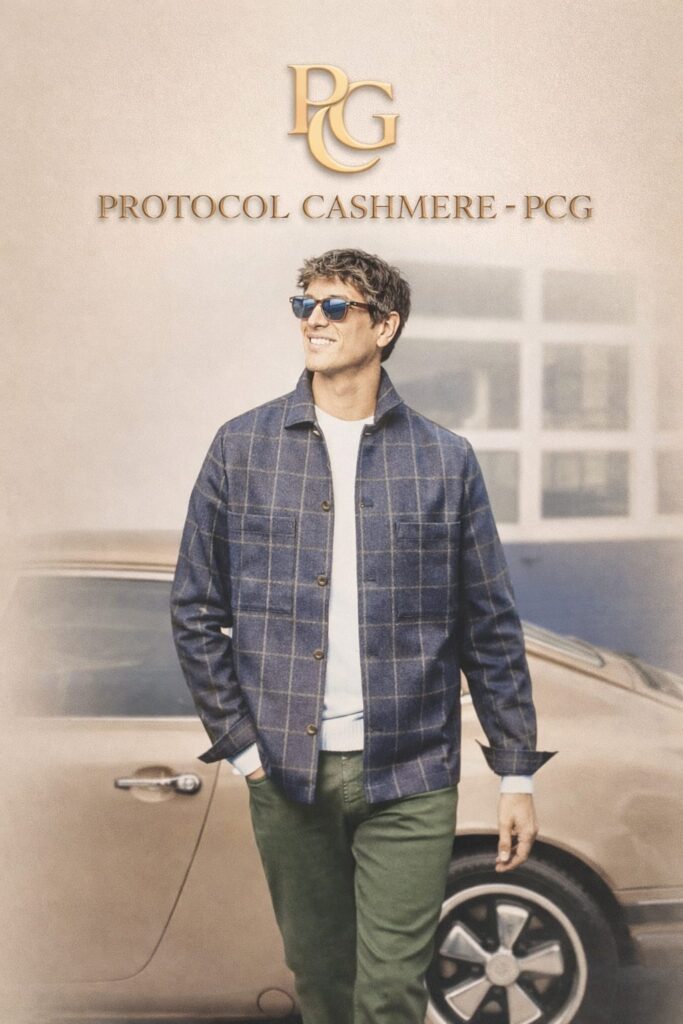

Our Process

We manage and coordinate every practical step involved in developing garments, working with factories, controlling quality, and delivering finished products to international buyers.

| Buyer Requirement & Initial Planning

When a buyer contacts PCG, the first step is understanding the product requirements in detail. This includes the type of garment, fabric preferences, target market, order quantity, price expectations, and delivery timeline.

Based on this information, we create a clear production plan before any sourcing or development begins.

| Fabric, Trim & Material Sourcing

Once requirements are confirmed, suitable fabrics, trims, and accessories are sourced from trusted suppliers. Materials are selected based on quality, durability, and buyer specifications.

This step ensures that the final product matches both design expectations and market standards.

| Sampling & Product Development

Before bulk production, samples are developed to confirm fabric choice, fit, construction, and finishing. This may include multiple revisions based on buyer feedback.

Only after the sample is approved does the project move forward, reducing the risk of errors during production.

| Factory Selection & Production Management

Factories are selected based on the product type, capacity, and technical capability. PCG coordinates production scheduling and follows up throughout the manufacturing process to ensure specifications and timelines are met.

This allows buyers to work with multiple factories through a single, controlled point of contact.

| Quality Control & Inspection

Quality checks are carried out during production and after completion. These inspections focus on workmanship, measurements, fabric quality, and finishing.

Any issues identified are addressed before packing, ensuring only approved goods proceed to shipment.

| Packing, Documentation & Shipment

After final approval, packing is arranged according to buyer requirements. Export documentation and shipment coordination are managed to ensure smooth delivery.

PCG oversees this stage to reduce delays and ensure compliance with export procedures.

OUR CLIENTS

Some Words From

our Buyer.

Dr. Gernot Lenz

CEO of Tom Tailor Group

“As a fashion brand, we had the opportunity to work with Protocol Cashemere and found their services highly professional and reliable. They supported us throughout the sourcing and production process, ensuring high-quality materials, timely deliveries, and clear communication. Our collaboration was smooth and productive, and we greatly value their expertise and dedication. We would highly recommend them to other brands seeking a trusted partner in the fashion industry.”

Daniel Grieder

Director of Hugo Boss

“We had a great experience collaborating with Protocol Cashemere. From sourcing the finest cashmere to managing production timelines, their team was professional, supportive, and easy to work with. They understood our brand’s needs and helped bring our designs to life with high-quality results. We truly appreciate their dedication and guidance throughout the process and would gladly work with them again.”

Daniel Ervér

CEO of H&M Group

“Collaborating with Protocol Cashemere has been a rewarding experience. Their expertise in cashmere sourcing, production, and quality management ensured that our collections were delivered on time and to the highest standards. Their team was responsive, professional, and committed to meeting our brand requirements, making them a trusted partner in the fashion supply chain.”